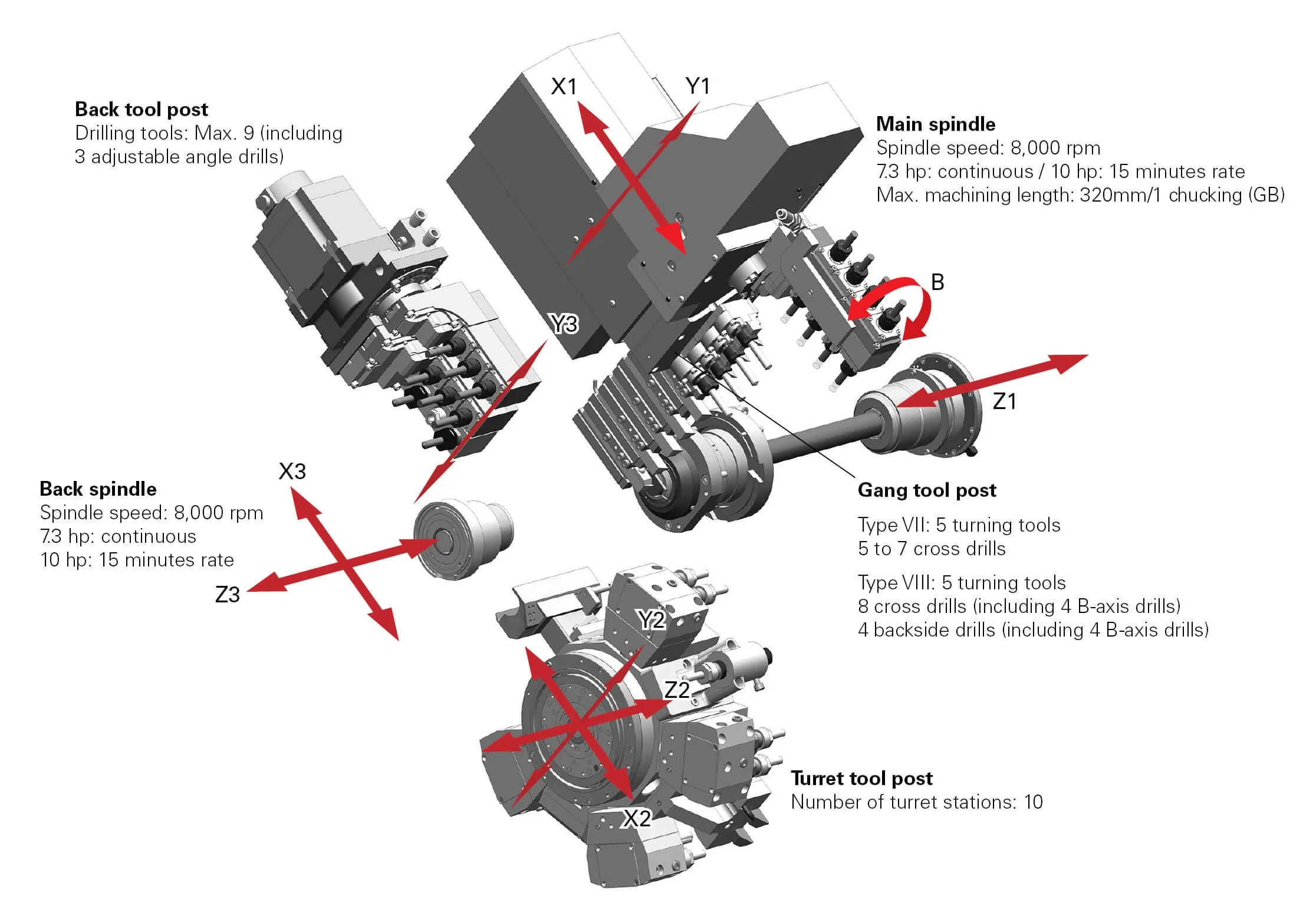

CINCOM M32 VII /M32 VIII

This next generation M32 includes additional features for improved performance, function and ease of use.

Single drive for rotary tools on the turret tool post, together with updated tooling

Higher torque and output for all motors, achieving powerful machining and high acceleration/deceleration

Optimal balance of strength and weight greatly improves rigidity

15 inch, touch screen operation panel with HMI

Larger door and window for improved operability and in-machine visibility

38mm oversized specification option available

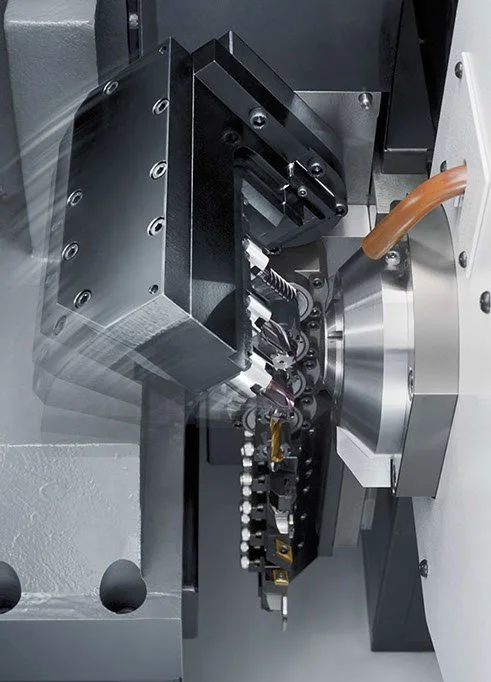

B axis with 3 rotary tools on the gang tool post (type VIII): The B axis is the slant axis in reference to the Y axis direction. When drilling a slanted hole on a conventional machine the adjustable angle spindle was required, but now rotary tools incorporating a B axis can be used to change the angle continuously allowing you to handle slanted holes at a number of angles. Contouring with simultaneous 4-axis control is also possible (the angle range is -10° to 95°).

Y Axis on the Back Tool Post: The back tool post can accommodate holders at 3 positions (2 positions for rotary tools and one for fixed tools) and up to nine tools can be used. All 3 rows are under Y3 axis control. The specifications of the outer diameter milling spindle (GSC1310), 3-drilling spindle (GSE1510) and 3-sleeve holder (GDF1501) are common to those used on the gang tool post and they can be used both on the gang tool post and the back tool post.

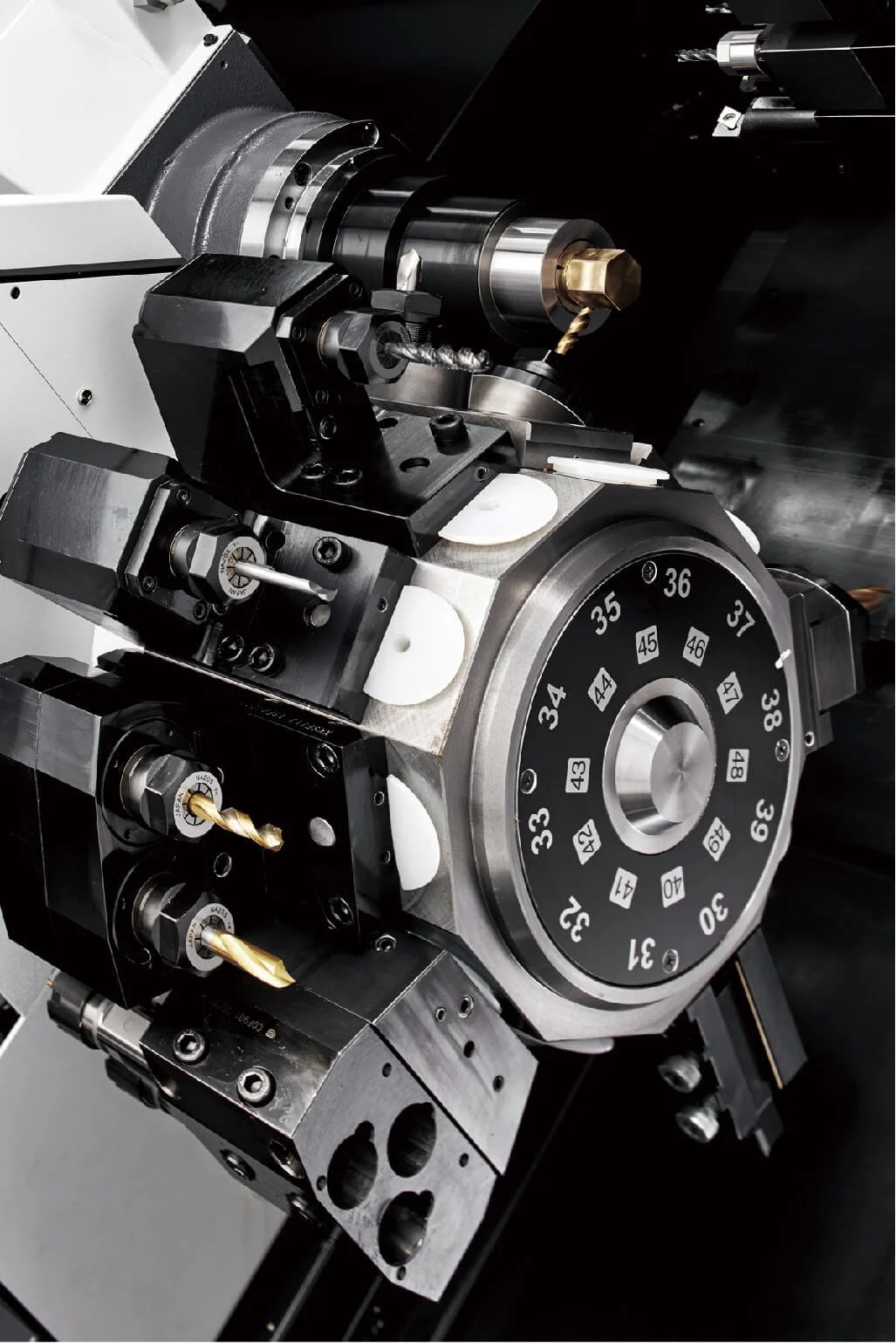

New Single Drive Turret: Employed for the first time with Cincom, a single drive mechanism where only the selected rotary tool rotates. Elimination of wasted rotation of non-selected tools enables powerful machining with high accuracy while suppressing heat generation, vibration and loss of power. It also extends the lives of gears and bearings, and reduces running cost.

Easily Switch Between Guide Bushing and Non-guide Bushing Type

The M32 is equipped with a detachable guide bushing as standard. This allows the machine to be used as a regular guide bushing type automatic lathe for long and small diameter workpieces. Once the guide bushing is removed, it can be used to machine short workpieces with less material waste.

Additional Details

LFV Technology

We provide next-generation machining tools to greatly reduce or eliminate a host of chip-related problems during cutting, taking your productivity to the next level.

LFV technology stands for low frequency vibration cutting. The servo axes are vibrated in the axial direction using a unique control technology where by cutting is performed while synchronizing

this vibration with the rotation of the spindle. This cutting method introduces regular "air-cutting" into the cycle, breaking up of chips into very small pieces making it the optimum processing method

for difficult-to-machine materials.